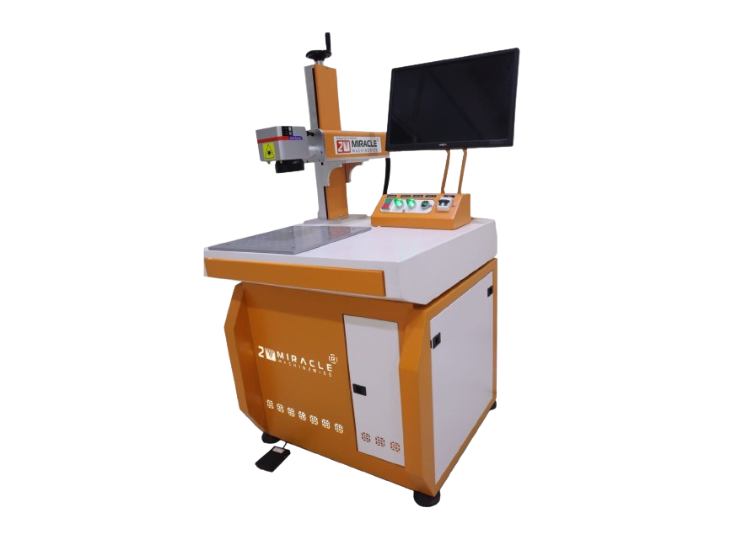

3D Laser Engraving Machine

Home » Products » Laser Marking Machine » 3D Laser Engraving Machine

3D Laser Marking & Engraving Machine by Miracle Machineries offer a wide variety

The 3D Laser Marking Machine utilizes a mirror galvanometer to scan the laser beam and create markings on the surface of the product. By adjusting the focus lens, the laser beam can be controlled not only on the x and y axes but also on the z axis.

3D Laser Engraving Machine by Miracle Machineries offer a wide variety

The 3D Laser Marking Machine utilizes a mirror galvanometer to scan the laser beam and create markings on the surface of the product. By adjusting the focus lens, the laser beam can be controlled not only on the x and y axes but also on the z axis.

Standard Working Process

01

Consultation

Except obtain procure which ever undertake all ever laborious who chooses to enjoy.

02

Detailed Proposal

Take trivial example which of ever undertakes some advantages physical exercise.

03

Project Installation

Idea pleasure work praisings painy was born account the system obtain some advantage.

04

Final Inspection

Teachings the great explorer of the truth, the master-builder all human happiness.

3D Software Extension

Moreover, an optional 3D Software Extension is available, which enhances the reproduction of intricate designs and engravings with precise detail. This extension is designed to manage STL files and enables the faithful 3D reproduction of solids, maintaining their true proportions. The supported file types for the 3D Laser Marking Machine include STL and 3D files.

3 Axis Auto-Movement

To facilitate efficient marking, the machine incorporates 3 Axis Auto-Movement functionality. This feature enables the management of axis positions through software, allowing for the sequential marking of multiple objects on the same tray, regardless of their varying shapes and sizes. By utilizing Cartesian coordinates, this module enables the programming of axis movements based on the objects’ positions, thereby increasing productivity through simultaneous marking.

- The 3D laser marking machine excels in its ability to dynamically focus across three axes, with a range of 25-30 mm. This capability enables the real-time tracking of deep curves and is supported by an advanced 3D scanning galvanometer head and control system. Whether for large-format marking, deep engraving, or curved surface marking, this machine can cater to a diverse range of processing needs.

- Furthermore, the focal length position of the laser marking machine can be precisely controlled, allowing for automatic adjustments along the Z-axis during the 3D deep marking process. This ensures minimal spot size and guarantees a uniform graphic effect after marking on the object.

Features Of 3D Laser Engraving Machine

- Hi-tech technology

- Permanent, high quality marks

- High efficiency and low operation cost

- Good accessibility, even to irregular surface

- Non-contact marking and no special working environmental needed

- The minimized metallurgical and mechanical damage

- Easy to automate and integrate (direct writing of patterns can established

- Using computer-controlled movement of the beam or sample)

- Precise beam positioning and a beam highly localized energy

- Transfer to the work piece

- High reproducible and high speed, effective

- Minimal heat load

- Contamination free

Technical Specifications of 3D Laser Engraving Machine

| Model | 2M F 3D – 50/100 Watts |

| Power | 20 W to 100 W |

| Wavelength | 1063 ±3 nm |

| Beam quality | <1.2 (M2) |

| Output power adjustment range | 10 – 100 % |

| Pulse repetition rate | 20 – 400 KHz |

| Power stability | <±1% |

| Focus spot diameter | <0.05mm |

| Working area | 70 X 70/100 X100/150 X 150/200 X 200/300 X 300 mm |

| Max marking depth | 1.2mm |

| Max marking speed | 1500 standard characters / second |

| Minimum line width | 0.05mm |

| Minimum character | 0.5mm |

| Repetition accuracy | ±0.003 mm |

| Operation system | Windows XP /7/8/10 |

| Cooling mode | Air cooling |

| Ambient temperature | 15°C – 35° C |

| Power requirement | 220V/single phase/50Hz/<600W |

| Life of laser module | 100000 Hrs |

| Guide Laser/Red Aiming Beam | Yes 660 nm |